What We do

We provide Food Safety, Quality and Product Development consulting services to help our customers on their journey of continuous improvement. Yale Lary also is an independent Safe Quality Foods Institute certified auditor. Yale previously served in leadership positions for Sara Lee and Sysco corporations. The majority of his his 30-year work life has been spent collaborating with teams in a variety of food manufacturing plants on subjects such as:

Supply Chain Risk Assessments – Supplier Expectation Programs – Ingredient Specifications – Plant Food Safety and Quality Plans and Training Programs – HACCP (USDA,FDA,CFIA) – Product Development – Formulations – Micro Control Validation Studies -Labeling – Sanitation Best Practices – – Rapid Food Micro Labs – Environmental Monitoring Programs – Shelf Life Programs – Food Processing CCP Validation Studies -Thermal Processing and Chilling Process Controls – Processing Aid (Raw & RTE) Intervention Validation Studies and Plant Programs.

He has Masters degrees in Meat Science and Agricultural Economics from Texas A&M University.

Most recently we made plant based eco friendly cleaning products to advance food safety. The formulas were such that the solutions cleaned and reduced bacteria counts when rinsing after a 2 minute contact time.

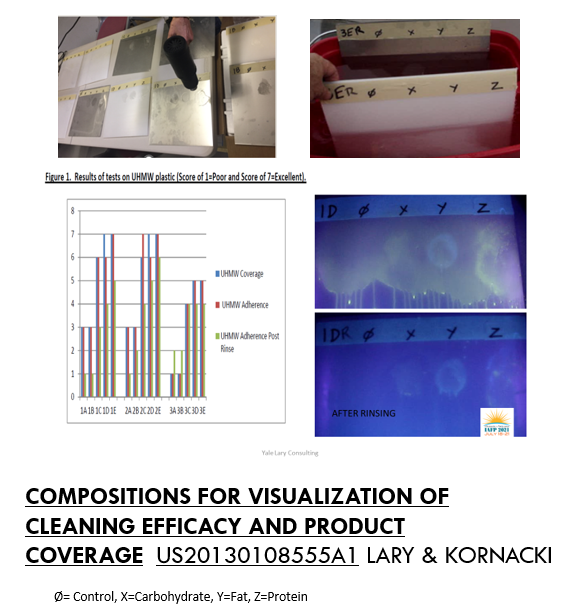

IzItClean and CleanIt formulas both qualify under the classification of A1 general cleaners for use in all food processing areas. They are non-corrosive, low VOC, low pH cleaners containing GRAS surfactants and acids. IzItClean was a patent pending NSF registered A1 general cleaner – it has fluorescing properties as well as antimicrobial properties.

The water soluble IzItClean formula is has bio-adhesive properties that holds the antimicrobial solution in contact with potential sources of bacteria. It also has a fluorescent tracer in the solution. After rinsing and inspecting under visible light, a Long Wave UV light inspection is performed to reveal presence or absence of fluorescence. It assists sanitarians to find bacteria harborages on, in niches, seals, gaskets, wear strips, sandwiches’, hollow tubing etc. and inside of food contact equipment.

Information is used to improve sanitation, maintenance procedures and highlight sanitary design challenges. It is a good tool for verifying and/or validating cleaning procedures.